See implemented code below.

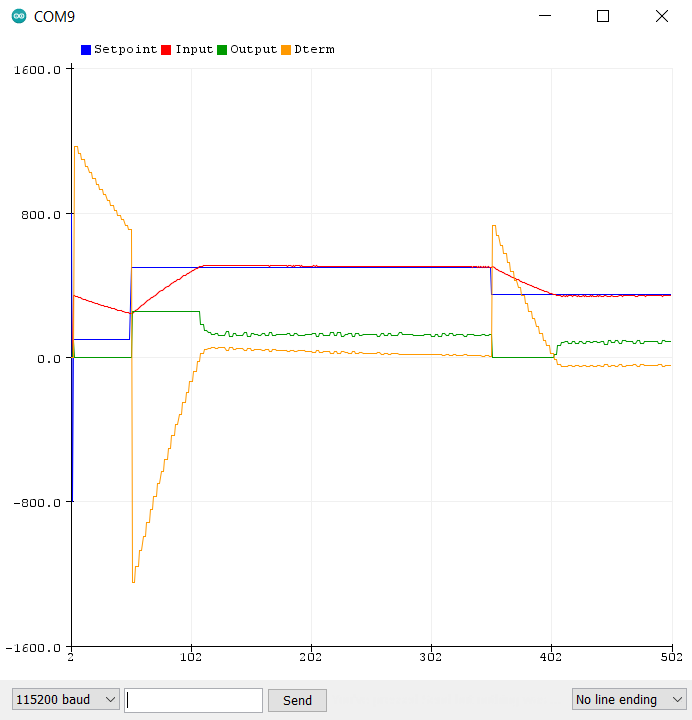

It seems like the example code is stuck in the 'stabilizing' fase and as such keeps executing case _myPID.autoTune->AUTOTUNE:

Am i doing something wrong?

`/******************************************************************************

AutoTune Filter DIRECT Example

Circuit: https://github.com/Dlloydev/QuickPID/wiki/AutoTune_RC_Filter

******************************************************************************/

#include "QuickPID.h"

#include <EEPROM.h>

int motor_links = 3;

int motor_rechts = 5;

int motor_enable = 4;

int sensorpiny = A5;

// Tilt setting values

float Voutmin1;

float Voutplus1;

float Vout0G1;

float Voutmin2;

float Voutplus2;

float Vout0G2;

float sensitivityX;

float sensitivityY;

byte n = 4; // ADC OVERAMPLING SETTING ADC 10+4 bits

float sensorx_v = 0, sensory_v = 0;

float sensorx = 0.0, sensory = 0.0;

float filt = 0.3; // filter

const uint32_t sampleTimeUs = 100000; // 10ms

const byte inputPin = 0;

const byte outputPin = 3;

const int outputMax = 255;

const int outputMin = 0;

bool printOrPlotter = 1; // on(1) monitor, off(0) plotter

float POn = 1.0; // proportional on Error to Measurement ratio (0.0-1.0), default = 1.0

float DOn = 0.0; // derivative on Error to Measurement ratio (0.0-1.0), default = 0.0

byte outputStep = 5;

byte hysteresis = 1;

int setpoint = 300; // 1/3 of range for symetrical waveform

int output = 85; // 1/3 of range for symetrical waveform

float Input, Output, Setpoint=220.0;

float Kp = 0, Ki = 0, Kd = 0;

bool pidLoop = false;

QuickPID _myPID = QuickPID(&Input, &Output, &Setpoint, Kp, Ki, Kd, POn, DOn, QuickPID::DIRECT);

void setup() {

Serial.begin(115200);

Serial.println("started");

pinMode(sensorpiny, INPUT);

pinMode (motor_links, OUTPUT);

pinMode (motor_rechts, OUTPUT);

pinMode (motor_enable, OUTPUT);

sensor_readsetup();

if (constrain(output, outputMin, outputMax - outputStep - 5) < output) {

Serial.println(F("AutoTune test exceeds outMax limit. Check output, hysteresis and outputStep values"));

while (1);

}

// Select one, reference: https://github.com/Dlloydev/QuickPID/wiki

//_myPID.AutoTune(tuningMethod::ZIEGLER_NICHOLS_PI);

_myPID.AutoTune(tuningMethod::ZIEGLER_NICHOLS_PID);

//_myPID.AutoTune(tuningMethod::TYREUS_LUYBEN_PI);

//_myPID.AutoTune(tuningMethod::TYREUS_LUYBEN_PID);

//_myPID.AutoTune(tuningMethod::CIANCONE_MARLIN_PI);

//_myPID.AutoTune(tuningMethod::CIANCONE_MARLIN_PID);

//_myPID.AutoTune(tuningMethod::AMIGOF_PID);

//_myPID.AutoTune(tuningMethod::PESSEN_INTEGRAL_PID);

//_myPID.AutoTune(tuningMethod::SOME_OVERSHOOT_PID);

//_myPID.AutoTune(tuningMethod::NO_OVERSHOOT_PID);

_myPID.autoTune->autoTuneConfig(outputStep, hysteresis, setpoint, output, QuickPID::DIRECT, printOrPlotter, sampleTimeUs);

}

void loop() {

if (_myPID.autoTune) // Avoid dereferencing nullptr after _myPID.clearAutoTune()

{

switch (_myPID.autoTune->autoTuneLoop()) {

case _myPID.autoTune->AUTOTUNE:

float raw = sensor_read(sensorpiny);

sensory_v = (filt * raw) + ((1.0 - filt) * sensory_v);

// sensory = ((sensory_v - Vout0G1) / sensitivityY) * 5;

Input = round (sensory_v*100.0);

// Serial.print ("Setpoint=");

// Serial.print (Setpoint);

// Serial.print (" || Input =");

// Serial.print (Input);

// Serial.print (" || Output=");

// Serial.println (Output);

if (Input < Setpoint) {

analogWrite(motor_rechts, Output);

analogWrite(motor_links, 0);

digitalWrite(motor_enable,HIGH);

}

else if (Input > Setpoint ) {

analogWrite(motor_rechts, 0);

analogWrite(motor_links, Output);

digitalWrite(motor_enable,HIGH);

}

else { analogWrite(motor_rechts, 0);

analogWrite(motor_links, 0);

digitalWrite(motor_enable,LOW);}

break;

case _myPID.autoTune->TUNINGS:

Serial.println("TUNING");

_myPID.autoTune->setAutoTuneConstants(&Kp, &Ki, &Kd); // set new tunings

_myPID.SetMode(QuickPID::AUTOMATIC); // setup PID

_myPID.SetSampleTimeUs(sampleTimeUs);

_myPID.SetTunings(Kp, Ki, Kd, POn, DOn); // apply new tunings to PID

Setpoint = 300.0;

break;

case _myPID.autoTune->CLR:

if (!pidLoop) {

_myPID.clearAutoTune(); // releases memory used by AutoTune object

pidLoop = true;

}

break;

}

}

if (pidLoop) {

if (printOrPlotter == 0) { // plotter

Serial.print("Setpoint:"); Serial.print(Setpoint); Serial.print(",");

Serial.print("Input:"); Serial.print(Input); Serial.print(",");

Serial.print("Output:"); Serial.print(Output); Serial.println(",");

}

float raw = sensor_read(sensorpiny);

sensory_v = (filt * raw) + ((1.0 - filt) * sensory_v);

// sensory = ((sensory_v - Vout0G1) / sensitivityY) * 5;

Input = sensory_v;

_myPID.Compute();

if (Input < Setpoint) {

analogWrite(motor_rechts, Output);

analogWrite(motor_links, 0);

digitalWrite(motor_enable,HIGH);

}

else if (Input > Setpoint ) {

analogWrite(motor_rechts, 0);

analogWrite(motor_links, Output);

digitalWrite(motor_enable,HIGH);

}

else { analogWrite(motor_rechts, 0);

analogWrite(motor_links, 0);

digitalWrite(motor_enable,LOW);}

}

}

float avg(int inputVal) {

static int arrDat[16];

static int pos;

static long sum;

pos++;

if (pos >= 16) pos = 0;

sum = sum - arrDat[pos] + inputVal;

arrDat[pos] = inputVal;

return (float)sum / 16.0;

}

// =============================================== FUNCTIONS ====================================================================

void loadsettings() { // load saved calibrate settings on start up

Voutmin1 = ( word(EEPROM.read(1), EEPROM.read(2))) / 1000.0;

Vout0G1 = ( word(EEPROM.read(3), EEPROM.read(4))) / 1000.0;

Voutplus1 = ( word(EEPROM.read(5), EEPROM.read(6))) / 1000.0;

Voutmin2 = (word(EEPROM.read(7), EEPROM.read(8))) / 1000.0;

Vout0G2 = (word(EEPROM.read(9), EEPROM.read(10))) / 1000.0;

Voutplus2 = (word(EEPROM.read(11), EEPROM.read(12))) / 1000.0;

// tilt sensor sensivity berekening.

sensitivityY = (Voutplus1 - Voutmin1) / 2;

sensitivityX = (Voutplus2 - Voutmin2) / 2;

}

float fSamples;

int samples;

void sensor_readsetup() { // ADc sensor setup

fSamples = pow(4, (float) n);

samples = (int)(fSamples + 0.5); // solves : when n = 3 get get pow(4,n) of 63

}

float sensor_read(byte input) { // Read sensor

// Decimation for Arduino ADC A0, averaged then decimated.

long dv = 0;

long derp = 0;

derp = millis();

for (byte avg = 0; avg < 2; avg++)

for (int j = 0; j < samples; j++) {

dv += analogRead(input); // analogRead(A0);

}

dv = (dv / 2); // average calc.

dv = dv >> n; // decimated

float Volt = dv * (5.0 / 16384.0); // conversion to voltage

return Volt;

}

`