"controller for 722.6 automatic transmission"

In a nutshell this was supposed to be reverse engineered transmission controller for 722.6 gearboxes found in many mercedes and chrysler vehicles, design is similar with more recent (7gtronic++) gear boxes, so in theory this could be applied with gentle care to work with those as well.

As with most things of life, this got bit out of hand and currently also controls boost, speedometer, rpm meter, fuelpumps and even horn, its also able to communicate with electrical steering wheel for menus and manual button shifts. Canbus interface is also supported on pcb but I have not yet utilized in any meaningful fashion.

First revision of working pcb (rev H) is done:

http://www.mui.fi/pcb-valmis.jpg

Fourth (rev K) just finished also and seems to pass testing;

http://www.mui.fi/smd-revk.jpg

and gerber files are available under pcb/ with boms.

Assembly instructions are not included, but I would be happy if someone would wish to write those.

- Not yet fully functional

- Use at your own risk!

Currently should work:

- Automatic downshift / upshift based on vehicle speed and throttle position (tested and works)

- Manual shifting (tested and works)

- Throttle position sensor (tested and works)

- Pressure maps for shifts and modulation pressure based on oil temperature and load, even when P/N/R (tested and works)

- W202 gearstick can be read (tested and works)

- SPI OLED for data output (tested and works)

- Boost sensor reading

- Boost limit maps (tested and works)

- Staged boost limiting (eg. drop boost on pre-shift, then continue shift etc.) (tested and works)

- w124 wire-speedometer (tested and works)

- Fuel pump control on idle (tested and works)

- vehicle speed reading based on tire size and diff ratio with and without engine rpm (tested and works)

- rpm reading (tested and works)

- Electric steering wheel support (manual shifts, menu control)

- oil temperature (tested and works)

- n2/n3 speed sensors (tested and works)

- evaluateGear, make sure which gear is in (tested and works)

- Torque converter lock based on default scenario (100% lock when on 5th gear, >80km/h and low load conditions)

- percentual map reads preferably without floats (eg. value between point x and y).

- External datalogging (format, method)

- Exhaust pressure sensor

- Pressure ratio calculation (intake vs exhaust)

- adaptative shift pressure (transloppy/maps)

Implemented but needs real life testing:

- w124 rpm meter (works in theory)

Work in progress:

- External datalogging (hardware implementation, visualization)

Currently datalogged (custom intervals, default is once per second):

- vehicle speed

- RPM

- Throttle position

- Coolant/Oil temperature

- ATF temperature

- Calculated load (engine rpm+throttle position+boost)

- Intake pressure

- Exhaust pressure

- Pressure difference

- Current boostlimit

- N2 & N3 transmission rpm sensors

- Evaluated gear (based on ratio calculation with abs-sensor and n2/n3 sensors)

- Current real gear ratio

- Current slippage

- Battery voltage

External datalogging is going to provide GPS location data and 3-axis acceleration data.

work by Markus Kovero ([email protected]) with regards and big thanks to:

- Tuomas Kantola for maps and related math

- Tommi Otsavaara for guiding in electronics

- Mikko Kovero and Pete for mechanical side of things

- Jami Karvanen for datalogging and frontend stuff

- Liia Ahola for pcb tracing

- Joosep Vahar for testing

- Toni Lassila and Jan Blonski for ideas

- Krzysztof Dymianiuk for enclosure solution and PCB design

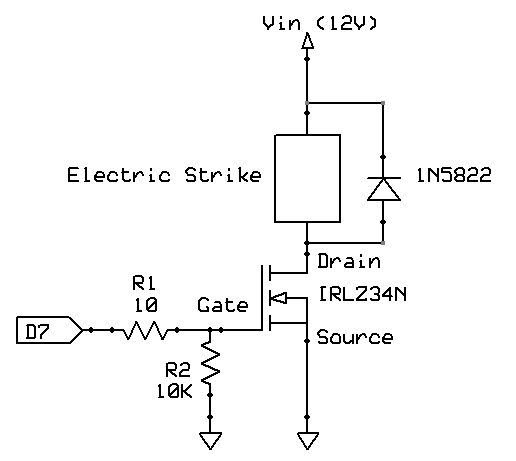

Schematics are for teensy, can be utilized with mega as well to some extent, tho mega support is going to be deprecated due obvious performance reasons.

There are four revisions of PCBs complete, tested and working "Rev H", "Rev I" and "Rev K".