In embroidery, there are many terms that have prevailed, as an abbreviation, as a derivative of the sewing area or independent technical terms. Without naming the terms of digitizing.

I initially had some problems to understand something (instructions on the internet, for example).

The translations into German are also a bit strange in some situations. That's why I have to write down these terms. The list is constantly growing, because you dive deeper into the topic.

Note: Cross references are still missing

Machine embroidery terminology and definitions

3D Embroidery / 3D Foam Embroidery :

Also known as Puff Embroidery, is a special technique to give three dimensional appearance to embroidery.

A layer of foam is placed under the area where the design will be embroidered. A high stitch density is

used to cut the foam for easy removal, and the foam beneath the design will not show through.

Aetzing :

The process used to create schiffli laces. The base fabric is dissolved, leaving the threads that have been stitched together to form the lace.

Alignment :

Using Rulers and Templates to correctly mark the position of your design.

Appliqué (APPL) :

Decoration or trimming cut from one fabric piece and stitched to another to add dimension.

Appliqué Outline :

Three lines of stitching around the fabric appliqued:

- Placement

- Tack Down / Dieline?

- Cover

Auto-Digitizing :

Turning artwork into embroidery design with software that does the digitizing for you automatically.

Not recommended!

Back Appliqué :

A fabric piece used behind a design, where the front fabric will be cut away to reveal the fabric beneath it.

Backing / Stabilizer :

Woven or nonwoven material used beneath the embroidered fabric to provide stability and support. Can be hooped with the fabric or placed between the machine's throat plate and the hooped item : Available in various weights and styles.

Basting Stitches :

Long stitches that go around the edge of your hoop & prevents shifting of material during embroidery.

Bean Stitch :

Three stitches placed back and forth between two points. Often used for outlining because it eliminates the need for repeatedly digitizing a single-ply running stitch outline.

Bias :

The direction across a fabric that is located at a 45-degree angle from the lengthwise or crosswise grain. The bias has high stretch and a very fluid drape.

Bias Tape :

Made from fabric strips cut on a 45-degree angle to the grainline, the bias cut creates an edging fabric that will stretch to enclose smooth or curved edges.

You can buy bias tape ready-made or make your own.

Birdnesting / Birds Nest / Nesting :

Thread collection between the fabric and the needle plate, resembling a bird's nest. May be caused by inadequate upper thread tension; upper thread not going through the take-up lever; upper thread not following the correct path; or flagging--the up and down motion caused in part by improper hooping.

Blanks :

Blank emblem shapes for monogrammers or apparel with no embroidery or printing; also refered to as "blank" goods.

Blatt Stitch :

Schiffli term meaning "to feed the yarn", which produces a long zigzag stitch with threads lying close together.

Blending (Gradients) :

A digitizing technique that makes different colors of thread flow together in a more pleasing manner. Relies heavily on variable densities.

Gives a design a more realistic (3D) look.

Bobbin :

Spool or reel that holds the bobbin thread in a sewing machine; this thread forms stitches on the fabric underside.

Bobbin Case :

Unit holding bobbin in a sewing machine.

Bobbin Embroidery :

Designs worked with the fabric hooped facedown and the specialty thread or ribbon wound onto the bobbin : Most effective for simple designs such as leaves and vines, or special effects with threads too heavy to be threaded through the needle.

Bobbin Thread :

Thread used on the bobbin of your embroidery machine. Often sold as a separate thread.

Bonding :

Permanently joining two fabrics together with a bonding agent. Also called heat sealing.

Boring :

Embroidered goods that have been punctured with a sharp pointed tool known as a bore,

the edges of the hole produced by the bore are embroidered, the hole is enlarged by the embroidery.

Buckram / Buckram Lining :

Coarsely-woven fabric stiffened with glue, used to stabilize items for embroidery : Commonly used in caps.

Canvas :

Closely woven heavy hemp, flax or cotton cloth used for tote bags, covers, etc.

Cap Frames :

Specialized embroidery frames designed to hold finished caps for embroidering.

Available in a variety of styles for various machines, with two basic styles being to

sew the finished cap flattened out, or sewing the finished cap (on a tubular machine) in its natural curve.

Card :

Disk containing computerized embroidery designs read by the embroidery machine's computer.

Cartoon :

Finished artwork of an embroidery design to be digitized.

Center Line Input :

When the embroidery software creates a satin stitch around a single line entered by the digitizer.

Center Point :

The center of the embroidery design.

Chain Stitch :

Stitch that resembles a chain link, formed with one thread fed from the bottom side of the fabric. Done on a manual or computerized machine with a hook that functions like a needle.

Check Spring :

Assists in upper thread tensioning and is used to detect upper thread breaks in many embroidery machine models.

Chenille :

Form of embroidery in which a loop (moss) stitch is formed on the top side of the fabric. Uses heavy yarns of wool, cotton, or acrylic.

Created by a chain stitch machine that has been adjusted to form this stitch type.

Cross Stitch :

Two stitches that cross to form an X.

Custom Designs :

Designs created by digitizing artwork or manipulating existing patterns.

Colorfill :

Combination of the Deboss and color, deboss then filled.

Column Stitch :

A series of zig-zag stitches placed closely together to form a column. Also know as a steil stitch or satin stitch.

Complex Fill :

Refers to a digitizing capability that allows areas to be designated as voids at the same time the design's edges are defined.

The design can thus be digitized as one fill area, instead of being broken down into multiple sections.

Condensed Format :

Method of embroidery digitizing where a design is saved in a skeletal form, so a proportionate number of stitches may later be

placed between defined points after a scale has been designated.

If a machine can read condensed format, the scale, density and stitch lengths in a design may be changed.

Deboss / Debossing :

Machine presses a die into the surface of the material, resulting in a depressed imprint.

Denier :

A system of measuring the weight of a continuous filament fiber.

In the United States, this measurement is used to number all manufactured fibers (both filament and staple), and silk, but excluding glass fiber.

The lower the number, the finer the fiber; the higher the number, the heavier the fiber.

Numerically, a denier is the equivalent to the weight in grams of 9,000 meters of continuous filament fiber.

600 vertical threads and 600 horizontal threads that help make a garment more durable and stronger.

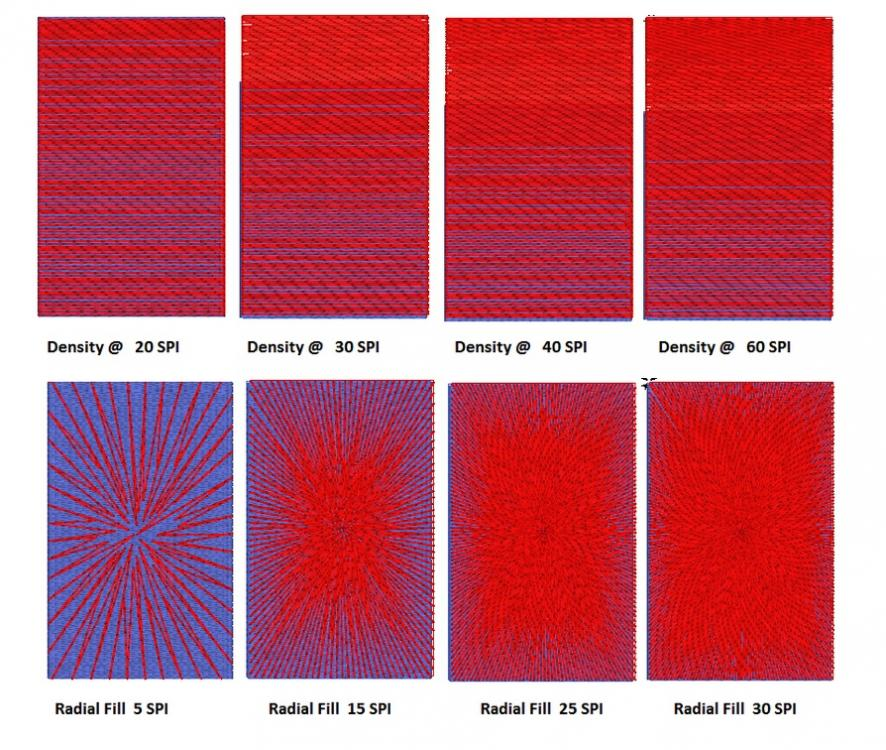

Density :

Number of stitches per given area.

Digitizer :

A person who digitizes.

Digitizing :

Conversion of artwork into a series of commands, read by an embroidery machine's computer via a card.

Double Stitched :

The finish on a sleeve and/or bottom hem that uses two needles to create parallel rows of visible stitching.

It gives the garment a cleaner, more finished look and adds durability.

Emboss / Embossing :

A surface effect achieved on fabric by means of passing cloth through a series of engraved rollers that impart figures or designs to its surface. Rollers work through heat and pressure.

Embroidery :

Decorative stitching on fabric.

Embroidery Arm / Embroidery Unit :

The moving part of your embroidery machine used when stitching out an embroidery design.

Embroidery Machine :

A computer controlled sewing machine that can stitch out patterns automatically.

Embroidery Point :

Unit of measurement in embroidery, in which 10 points equals 1 mm.

Embroidery Thread :

Sewing thread design specially for machine embroidery. Most often polyester or rayon.

Emblem / Patch :

Embroidered design with a finished edge, applied to a garment or item after stitching.

Expanded Format :

A design program where individual stitches in a design have been specifically digitized for a certain size.

Designs digitized in this format cannot generally be enlarged or reduced more than 10 to 20 percent without

distortion because stitch count remains constant.

Fabric Glue Stick :

Used in place of spray adhesive to hold fabric or item in place on stabilizer while stitching is started.

Facing :

Material hooped or placed on top of fabric, with a nap or surface texture to contain the nap and hold the embroidery stitches above it.

Fancy Fills :

See Speciality Fills.

Feather Stitching :

Lightweight designs constructed of run stitches. Ideal for tricots, nylons and taffetas.

Felt :

Non-woven fabric made from wool, fur or hair matted together by heat, moisture and pressure. Often used for patches or stitched samples.

Fill Stitch (FS) :

A series of running stitches commonly used to cover large areas. Different fill patterns are created by altering the stitch angle, length or repeat sequence.

Finishing :

Processes done after the embroidery is completed, including trimming loose threads, removing excess facing or backing, and pressing or steaming to remove puckers and hoop marks.

Flagging :

Up-and-down motion of the fabric under the needle action, caused by improper hooping. Results in poor registration, unsatisfactory stitch formation and bird-nesting.

Flat Embroidery :

Embroidery that is framed in hoops, usually exclusively on the top of the embroidery machine's hook assembly.

Float :

Longer-than-normal satin stitches that lay on top of a design, or the stitches made when the needle is disconnecting from the design; later removed.

Foil :

Comes in several colors, with the most popular being red, gold and silver. To use foil, screen print the garment as usual, place the foil over the wet ink, remove the garment from the platen, and cure it with a heat press. The printed and foiled garment can be flash dried before it's removed from the platen, and other colors then can be printed on top of the foil.

FOX Test :

Method of testing thread tension and soundness of timing.

Sew the word FOX in one inch satin stitch block letters.

Examine the reverse side for correctly balanced ratio of one-third bobbin thread to two-thirds top thread.

Frame :

Holding device for inserting the hoop beneath the needle to maintain stability during the embroidery process.

Frame Sash :

Part of the pantograph to hold the frames. Also called a sash.

Free Motion :

Hand-manipulated embroidery done with a zigzag stitch, available on most machines.

Free Standing Lace (FSL) :

Style of embroidery design stitched onto water-soluable stabilizer that is then disintegrated leaving a "thread-only" stitch out.

French Knots :

A stitch featuring a raised, knotted center.

Fringe :

Threads that are cut and hang loosely from the edge of a design.

Frog Stitch :

Tongue-in-cheek references to stitches put in the wrong place. - You have to "rip" them out... "ribbit-ribbit"

Fusible Mesh :

An open-weave stabilizer that is bonded to fabric with heat.

Gapping :

Where the fabric is seen through the embroidery design either in the middle of the pattern or on the edge.

Geflect Stitch :

See Fill Stitch.

Grain :

See Twill Weave.

Grommet :

An eyelet of firm material to strengthen or protect an opening. Often Brass.

Guide Stitch :

Series of stitches used to align embroideries in multi-hooping situations or to assist in fabric placement for appliqué.

H Test :

Method of testing thread tension. Stitch one inch block letters for each needle bar.

The reverse side of the completed embroidery should show a ratio of two-thirds top thread to one-third bobbin thread.

Hand :

The way the fabric feels when it's touched. Terms like softness, crispness, dryness and silkiness are all used to describe the hand of the fabric.

Heirloom Embroidery :

Embroidered goods designed to be passed down from generation to generation.

Hardware :

Computer equipment, digitizer, modem and sewing machine.

Heat 'N Gone :

A topper that dissolves with the heat of an iron.

Hook :

Holds the bobbin case in the machine and plays a vital role in stitch formation.

Making two complete rotations for each stitch, its point meets a loop of top thread at a precisely-timed moment and distance (gap) to form a stitch.

Hook Timing :

Proper synchronization of hook's rotary and needle's up/down movement; necessary to form stitches.

Hole Cutting :

A technique used in digitizing where area under another area is removed.

Hoop :

Wood, plastic or steel device used to tightly grip the fabric and stabilizer between an inner and outer ring; Attaches to machine's frame; Designed to hold fabric taut against the machine bed for embroidery.

Hoop (n) :

A device made from wood, plastic, or steel with which fabric is held in place for machine embroidering.

A frame that attaches to the embroidery unit to hold the fabric taut while stitching.

Hoop (v) :

The process of placing the fabric and/or stabilizer into the embroidery hoop.

Hooping :

Process of putting the stabilizer & fabric in the hoop.

Hoopless Embroidery :

Technique of hooping stabilizer and NOT hooping the fabric or project to be embroidered.

Hooping Board :

Device that aids in precise placement and uniformity in hooping, subsequent garments or items for embroidery.

In The Hoop (ITH) :

A design that stitches out a complete project wihtout un-hooping the fabric.

Interlock Stitch :

Two or more rows of overlapping satin stitches.

Jumbo Rotary Hook :

Rotary hook which holds a bobbin case with a much larger thread capacity than a standard hook.

Jump Stitch :

A stitch that moves the needle from one part of a design to another part. Usually removed after design is finished stitching.

Lettering :

Refers to the embroidery of letters, either made completely with stitches, or a combination of cutout appliqué pieces and stitching.

Line Work (LW) :

There are major 3 types of Line Work :

- Red Work (RW) : Is a single line of stitching done in a red work stitch all in one color.

- Blue Work (BW) : Is a single line of stitching done in a triple bean stitch all in one color.

- Color Work (CW) : Is a single line of stitching done in a red work or triple bean but is done in multiple colors.

Lint Brush :

Use to get the fuzz from under the needle plate on your machine.

Lip Hooping :

Known as recessed hooping, this technique is useful when hooping bulky or slick fabrics such as insulated jackets.

Lock Stitch :

Formed by three or four consecutive short, tight threads stitched at end of embroidery to prevent raveling.

Lock Stitch Machine :

Machine which forms a stitch using a hook and needle. Includes home sewing machines, as well as computerized embroidery machines.

Looping :

Loops on the embroidery surface generally caused by poor top tension or tension problems.

Typically occurs when polyester top thread has been improperly tensioned.

Low Profile Cap :

A cap style with a low slope that is more closely fitted to the head. Can be either structured or unstructured.

Marking :

Making temporary marks on fabric to aid in hoop placement and to reference needle beginning points.

Merrowed Edge :

A merrowed edge is a 3/16" overlocked sewn edge done to secure the cut fabric from unravelling. Usually used for the bottom edge of emblems, pant cuffs or garment interior cut edges.

Metafill :

A needle with an elongated eye, especially useful when using decorative or metallic threads.

Monogram :

Embroidered design composed of one or more letters, usually one's initials.

Moss Stitch :

See Chenille.

Motif :

A single embroidered design.

Nap :

A fuzzy or downy surface of fabric covering either one side or both, produced by brushing

Network :

Links computer, digitizer and embroidery machine together, usually via a modem.

Needle bar :

Bar that holds the needle and regulates the distance to which the needle is driven into the bobbin assembly.

Nippers :

See Thread Clippers.

No-Spray Adhesive :

Use the blue painters tape. Cheaper and less hazardous than spray glue.

Offset :

The ability to move the pantograph out of the design with a specific movement and then return to the original point.

Used for placing appliquès.

Origin :

The starting point of your design.

Overrun :

Specialties produced in excess of the number originally ordered.

Pantograph :

A bar, rack, or holder that frames or holding fixtures are attached to.

The pantograph moves in X and Y directions to form the embroidery design,

controlled electronically or mechanically depending on the machine.

Pattern :

The digitized design.

Pencil Rub / Pencil Transfer :

A low-cost way of producing a "sample" of an embroidery design.

Consists literally of a piece of tracing paper placed over a sewout and rubbed lightly with a pencil to produce an impression of the embroidery.

Piqué :

A fabric of cotton or spun rayon woven lengthwise with raised cords.

Pre-tensioner :

Thread tension assemblies that are before the main tension assembly in the thread path.

The function of the pre-tensioner is to apply a light amount of tension in order to make the main tensioner work.

Presser Foot :

Metal device that touches the goods being embroidered while the needle is in the goods.

The main function of the presser foot is to hold the material being embroidered until the hook point catches the thread loop formed by the needle rise.

Puckering / Pucker :

Result of fabric being gathered by the stitches. Possible causes include loose hooping, lack of or improper backing, incorrect tension or a dull needle.

Puff Embroidery :

Stitching a dense motif over embroidery/craft foam to create a three-dimensional effect.

Punching :

See Digitizing.

Push and Pull :

The distortion of design elements caused by the interaction of the needle, thread, backing and machine tensions.

In most cases the element and/or the fabric are causing either push or pull, but not both.

The exception to this rule tends to be in satin stitch columns, whether in a letter, outline or otherwise.

Satin columns can pull in on the ends (thus reducing column width) and push out on the sides (thus increasing column length).

To counteract these distortions, digitizers use a technique call Compensation.

Push-Pull Compensation :

Fine-tuning digitizer includes in a design to prevent thread direction from affecting design symetry.

Registration :

Correctly aligning all stitches and design elements.

Repeat :

Layout used for making emblems or designs on a fabric span that are repeated at regular intervals.

Resizing :

The ability to scale a design to different sizes; May cause density problems unless stitch count can be altered.

Running Stitch :

A single stitch between two points, used for outlining and fine detail.

Satin Stitch :

Formed by closely arranged zigzag stitches; Can be stitched at any angle and with varying lengths.

Short Stitch :

A digitizing technique that places shorter stitches in curves and corners to avoid an unnecessary bulky buildup of stitches.

Software :

Computer programs or design cards.

Specialty Fill :

Fill stitch capability that produces a design in relief.

Specialty Threads :

Threads designed for effects such as shine, glitter, iridescence or thickness. The threads often are made from synthetic materials including rayon, mercerized cotton, metallic and textured nylon.

SPI :

Stitches per inch.

SPM :

Stitches per minute.

Spray Adhesive :

Used for holding fabric in place when doing applique and in the hoop projects.

Stabilizer :

See "Backing" and "Facing".

Stitch Processing :

The calculation of stitch information by means of specialized software, allowing scaling of expanded format designs with density compensation.

Steil Stitch :

See Column Stitch.

Stock Designs :

Embroidery designs readily available on disks or brand-specific cards.

Swatch :

A small sample of material used for inspection, comparison, construction, color, finish and sales purposes.

Swiss Embroidery :

- Satin stitch embroidery.

- Also recalls the origins of an automated embroidery machine that was developed in the 1800s by Isaak Groebli. Embroidery remains a government-supported industry in Switzerland today.

Tack Down Stitch :

Line of stitches that hold applique material in place on top of bacground fabric.

Tackle Twill :

Letters or numbers cut from polyester or rayon twill fabric that are commonly used for athletic teams and organizations.

Take-up Spring :

See Check Spring.

Tatami Stitch :

Series of run stitches, commonly used to cover large areas. Different fill patterns can be created by varying the stitch length, angle or sequence.

Tear-Away :

A type of stabilizer that can be easily torn to remove excess after embroidery is finished stitching.

Template (Digitizing) :

When opening artwork to digitize you use the artwork as a guide or "template" for the design.

Template (Embroidery) :

Print out of your design on paper used to help with determining proper design placement on fabric.

Tension :

Tautness of thread when forming stitches. Top thread tension, as well as bobbin thread tension, needs to be set.

Proper thread tension is achieved when about one third of the thread showing on the underside of the fabric on a column stitch is bobbin thread.

Tensioner :

Device used to adjust the tautness of thread when forming stitches.

Thread :

Fine cord of natural or synthetic material with two or more elements twisted together and used for stitching.

Machine embroidery threads come in :

- Rayon (high sheen)

- Cotton (duller finish)

- Polyester (strong and colorfast)

- Metallic (synthetic core wrapped with metal foil or thin slivers of metal foil)

- Acrylic (sheen similar to rayon).

Thread Clippers :

Small cutting utensil with a spring action that is operated by the thumb in a hole on the top blade and the fingers cupped around the bottom blade.

Useful for quick thread cutting, but unsuitable for detailed trimming or removal of backing.

Tie In Stitches :

Small stitches used at the beginning of a sewing cycle, particularly on satin stitches, to prevent the thread from pulling out of the embroidery.

Tie Off Stitches :

Small stitches, usually about 1 mm in length that “lock” the stitches in the fabric to prevent the stitch from unraveling when the thread is trimmed.

Without Tie off stitches the thread can potentially unravel and destroy the embroidery.

They are particularly necessary when making satin stitches wider than 1.2mm, as satin stitches have a tendency to unravel more easily than running or fill stitches.

Topper / Toppping :

A thin material placed on top of fabric to hold down nap. Usually designed to wash out.

Trapunto :

A form of 3D embroidery. An area is stitched to create a pocket between the fabric and backing, which is then stuffed from the back with some type of fluffy filling.

Trimming :

The action of cutting loose thread, removing backing, etc., from the final embroidered product.

Tubular Embroidery :

Embroidery produced on an embroidery machine which allows tubular fabric or pre-assembled garments to be placed around the hook assembly. Allows sewing of the front of a garment without sewing through the front and back of it.

Tulle :

A fine net of acetate, nylon, rayon or silk used for the embroidery of imitation laces.

Twill :

Characterized by a diagonal rib. Twill weaves are used to produce a strong, durable, firm fabric usually cotton or polyester.

Twill Weave / Grain :

A basic weave in which the fabrics are constructed by interlacing warp and filling yarns in a progressive alternation which

creates a diagonal effect on the face, or right side, of the fabric.

In some twill weave fabrics, the diagonal effect may also be seen clearly on the backside of the fabric.

Two-ply Stitch :

A double running stitch. The stitch is formed by the machine sewing a complete running stitch area and then coming back over the same area and stopping where it started. Sews from Point A to Point B and then from Point B to Point A.

Underlay :

Used under the regular stitching in a design. The stitches are placed to provide stability to the fabric and to create different effects.

Underlay is normally a series of running stitches or a very light density fill often placed in the opposite direction that the stitching w/ill go.

Underlay Stitch :

Stitches, laid down before other design elements to help stabilize fabrics.

Variable Sizing :

Ability to scale a design to different sizes.

Verify :

Sample sewout or print-out of a new embroidery design to make sure the pattern is correct.

*Walk Stitch :

See Running Stitch.

Wash-Away :

A type of stabilizer that can be removed by rinsing project after design is stitched out.

Water Soluble Stabilizer (WSS) :

A stabilizer that melts when exposed to water.

Zig-Zag :

Stitches that progress in an alternating-angle (zig zag) fashion; typically used for final stitching on appliqué and tackle twill.