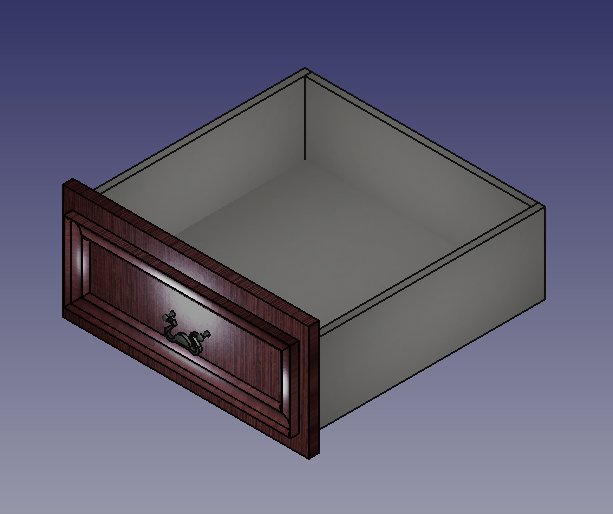

FreeCAD is great software. This workbench extends the features of FreeCAD for Woodworking. The main goal for this workbench is to make the furniture designing process in FreeCAD simpler.

-

Furniture from scratch & redesign: YouTube playlist

-

Cut-list, BOM, dimensions: YouTube playlist

-

Joinery examples: YouTube playlist

-

Parametrization solutions: YouTube playlist

-

Workbench features & development: YouTube playlist

-

Woodworking workbench YouTube channel: all videos

-

Woodworking workbench documentation: Woodworking/Docs

New significant changes since the last stable version:

- tenon option at magicDowels tool

- getDimensions engine improved

Step 0. Install correct FreeCAD version:

- Download and install: FreeCAD 0.21.2

Step 1. Get FreeCAD Mod folder localization:

-

From FreeCAD python console run command:

FreeCAD.ConfigDump()["UserAppData"] -

If there is no

Modfolder, create it.

Step 2. Install Woodworking workbench:

-

Go to FreeCAD

Moddirectory, for example, in Xubuntu operating system:cd ~/.local/share/FreeCAD/Mod/ -

Get the latest Woodworking workbench repository:

git clone https://github.com/dprojects/Woodworking.git

Step 2. Installation in other operating systems:

- Download and unpack

Woodworkingrepository. - Copy the folder

Woodworkingto the FreeCAD module directory (Modfolder).

Note: You can update this workbench later via debuginfo tool.

-

Stable certified versions download at: Woodworking/releases

-

For cutting edge features download: the master branch

-

Current development platform:

OS: Ubuntu 22.04.3 LTS (XFCE/xubuntu) Word size of FreeCAD: 64-bit Version: 0.21.2.33771 (Git) AppImage Build type: Release Branch: (HEAD detached at 0.21.2) Hash: b9bfa5c5507506e4515816414cd27f4851d00489 Python 3.10.13, Qt 5.15.8, Coin 4.0.0, Vtk 9.2.6, OCC 7.6.3 Locale: English/United States (en_US) Installed mods: * Woodworking 0.21.2.33771

Note:

- I don't have

WindowsormacOS, so I am not able to test and certify this workbench for those systems. However, if you useFreeCAD AppImagethere is a good chance this will be working correctly. - To get better stability make sure your current Woodworking workbench version has always the same version number as the FreeCAD version. You can also verify this via debuginfo tool.

- Issue: Cut-list, BOM, report

toPrintis not in the center of the page.- Workaround: FreeCAD 0.21.2 has bug related to the TechDraw template. The TechDraw template size is always zero, so the center of the page cannot be calculated correctly. If this is issue for you, can adjust the report manually or please try higher FreeCAD version with this bug fixed (0.22).

This woodworking workbench is delivered with several useful extras:

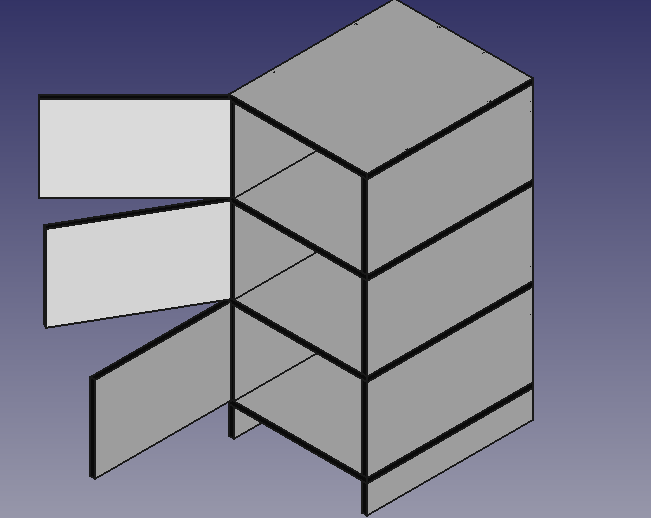

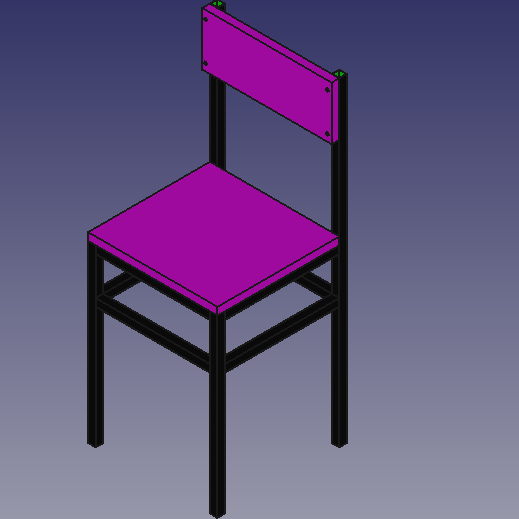

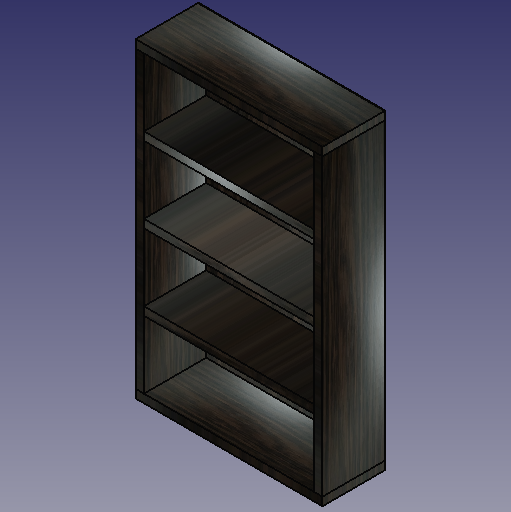

- Fully parametric examples - this folder inside woodworking workbench contains sample furniture projects. All of the furniture examples are parametric. So, you can quickly adopt it to your current project, without designing e.g. bookcase from scratch. You can also add decoration, if needed, or even merge with other projects.

- Fixture examples - this is new approach to 3D modeling. For example you can replace any Cylinder with realistic looking detailed screw. This is very powerful feature and gives a lot of flexibility and simplifies the process of making model detailed.

- Texture samples - sample textures for woodworking projects purposes.

The Woodworking workbench also has an API for developers. This library contains functions that solve the Topology Naming Problem. You can also leaglly create your own tools and extend the workbench in your private repository in accordance with the MIT license:

- View library API documentation: MagicPanelsAPI.md

- View library code: MagicPanels.py

- Download & install library: raw version

Note:

- If you have Woodowrking workbench installed you don't have to install the

MagicPanelslibrary manaually. Also you can view the library directly from Woodworking workbench via: scanObjects tool. - For programming I use simple Krusader with

F4KWrite editor. I have set tabulators as indent:Settings->Configure Editor->Editing->Indentation->Tabulators->Tab width: 4 characters.

For Woodworking workbench translation see dedicated directory: translations

MIT for all Woodworking workbench content.

- For questions, comments, feature requests, improvements, please open issue at: issue tracker

- Also we can discuss at: FreeCAD forum thread

|

|

|

|

|

|

|

|